KAG

New member

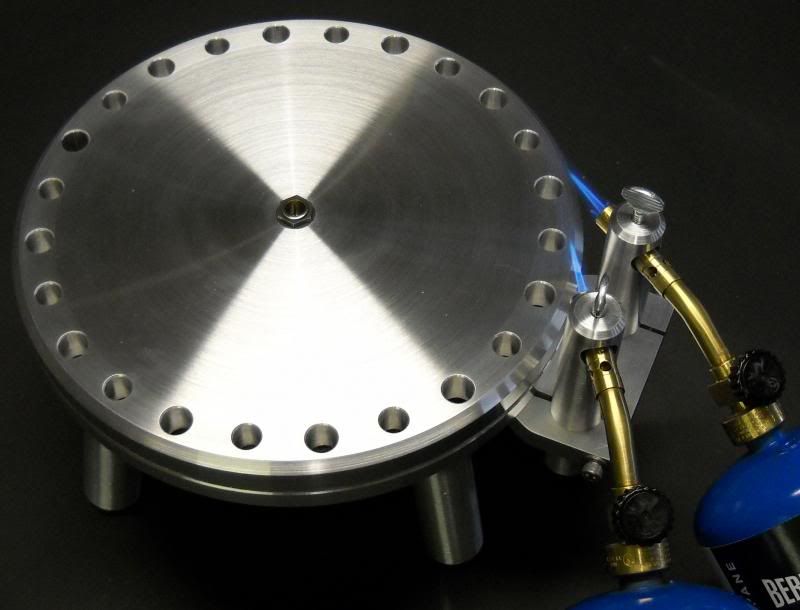

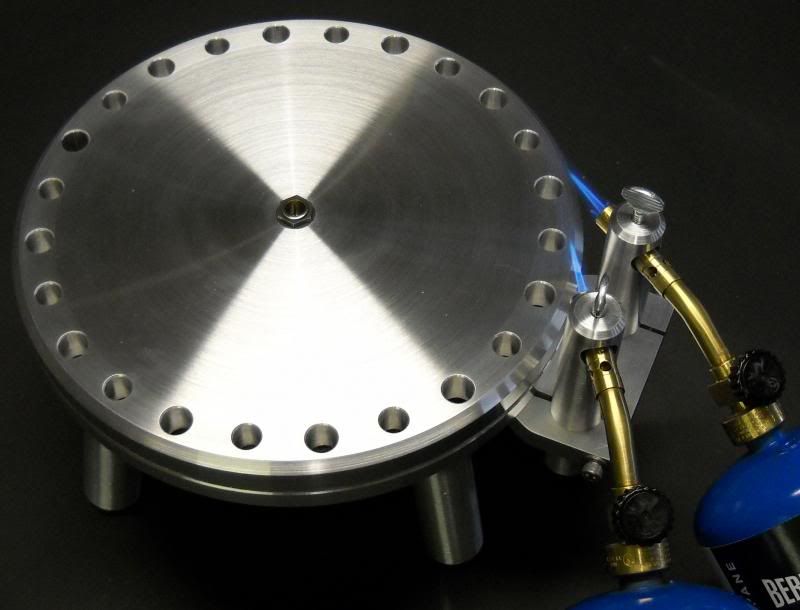

Well started looking at them as I have lots of 25wssm brass that needs annealed and given the cost of new brass I am exploring getting an annealing machine. I have annealed brass with a torch and pan of water but after 30 or so cases the thrill is gone. I figure I could use it on my other brass I have as well as make it easier to help form brass for wildcats and such.

Anyone have one that can comment on it as far as ....is it worth it and such?

http://annealingmachines.com/home

Anyone have one that can comment on it as far as ....is it worth it and such?

http://annealingmachines.com/home