I have had 2 people contact me and ask me questions about how I go about making a call. For a rookie that makes me feel pretty good. Being the redneck hillbilly I am, trying to do with not enough tools, and questionable skills /ubbthreads/images/graemlins/wink.gif I thought I would share how I go about doing it. I know it isnt the best method, but making do with what I have its how I get thru life. /ubbthreads/images/graemlins/smiliesmack.gif

Making a call is much like making a wood fishing lure, kinda round, and hole down the middle. /ubbthreads/images/graemlins/wink.gif I have made a lot of fishing lures so a call wasnt to much of a leap. /ubbthreads/images/graemlins/confused1.gif

One of my biggest problem is getting the hole down the middle of the call. With my prehistoric lathe, I have no tools to do this with on the lathe.

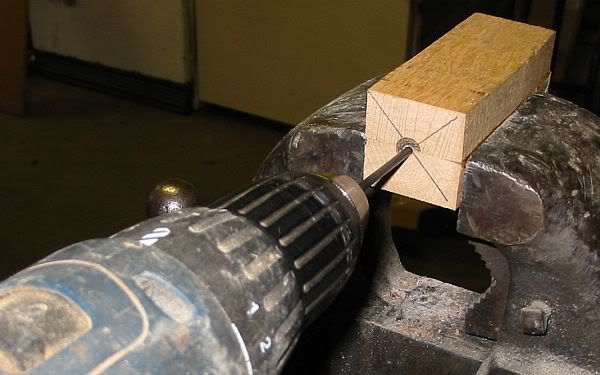

First starting with a block of wood I mark centers on each end and use an 1/8 inch drill bit to make a very shallow hole on each end.

Then I have to set up my drill press. I take a piece of scrap wood and drive a nail thru it with about an 1/8 of an inch of the nail sticking up, and clamp it in the drill press with the nail directly under the drill bit. I use a longer drill bit to make sure it is located where it needs to be. I have to drill the hole prior to lathing or I would never be able to drill a hole after lathing and keep it in the center. /ubbthreads/images/graemlins/crazy.gif

Then I swap out the longer drill bit and put in a shorter drill bit that still allows me to get my piece of wood under the drill bit. I set the piece of wood on the nail, with the nail in the shallow hole I drilled earlier I know my drill bit is headed down the middle of the wood. I drill both ends of the wood, the length of throw on my drill press, which isnt much. /ubbthreads/images/graemlins/smiliesmack.gif

I now have a hole into each end of the wood that should be on the same axis assuming I had the the drill press set up correct. These holes work as a guide for my long drill bit to guide it thru the center of the wood. When I hand drill the balance of the hole I should hit one hole from the other in the middle of the wood if I did everything correct.

Now I put the piece of wood on the lathe and put the points on the lathe ends in the drilled hole, so I am spinning on my pre-drilled hole. I lathe up the desired shape.

Next comes my next big problem of removing the wood from the center of the call with a lathe with no attachments or accessories to make this easy. /ubbthreads/images/graemlins/smiliesmack.gif I take a short shallow cut from each end of the piece of wood with a lathe tool so I have a mark I need to hand ream the wood to later. The next pic shows the cut at a funny angle trying to mark the inner edge of the call where I will ream to.

Then I sand the outside of the call on the lathe

For some reason I like a rounded hole for the lanyard to attach to the call with. I dont have a lathe tool to accomplish this, so I use a rasp. /ubbthreads/images/graemlins/shocked.gif

Now I take the piece of wood off the lathe and cut the ends off where the lathe grabbed onto the wood. I run a 9/32 drill bit down the 1/8th inch hole to hold the reed sleeve from each end till it meets in the middle. The drill bit will follow the predrilled hole.

Then I take the biggest drill bit I have which is 1/2 inch and I go about an inch in on the mouthpiece, and quite a ways in on the other end, leaving about an inch or so of 9/32 hole down the middle where the reed holder will be located. I mark the drill bit with tape so I know where to quit drilling from the bell end.