Swage or cut primer crimp

- Thread starter bigtommy

- Start date

I have the Dillon and the press mounted RCBS (old school). I used the RCBS but moved to the Dillon. I have used the Dillon for well over 20 years but lately I have been cutting them using a deburring tool in my drill. The cutting is far faster and easier on my elbows and wrists. I found myself with 2,000 6.8's that were crimped a about a yer ago and the drill sure made short work of them. It isn't hard once you develop the touch.

I have had no issues i over/undercutting. Primers are staying in pace during firing top end loads and pocket integrity has not suffered based on what I'm seeing. I believe like many surgeons do, "To cut is to cure."

Greg

I have had no issues i over/undercutting. Primers are staying in pace during firing top end loads and pocket integrity has not suffered based on what I'm seeing. I believe like many surgeons do, "To cut is to cure."

Greg

Plant.One

Well-known member

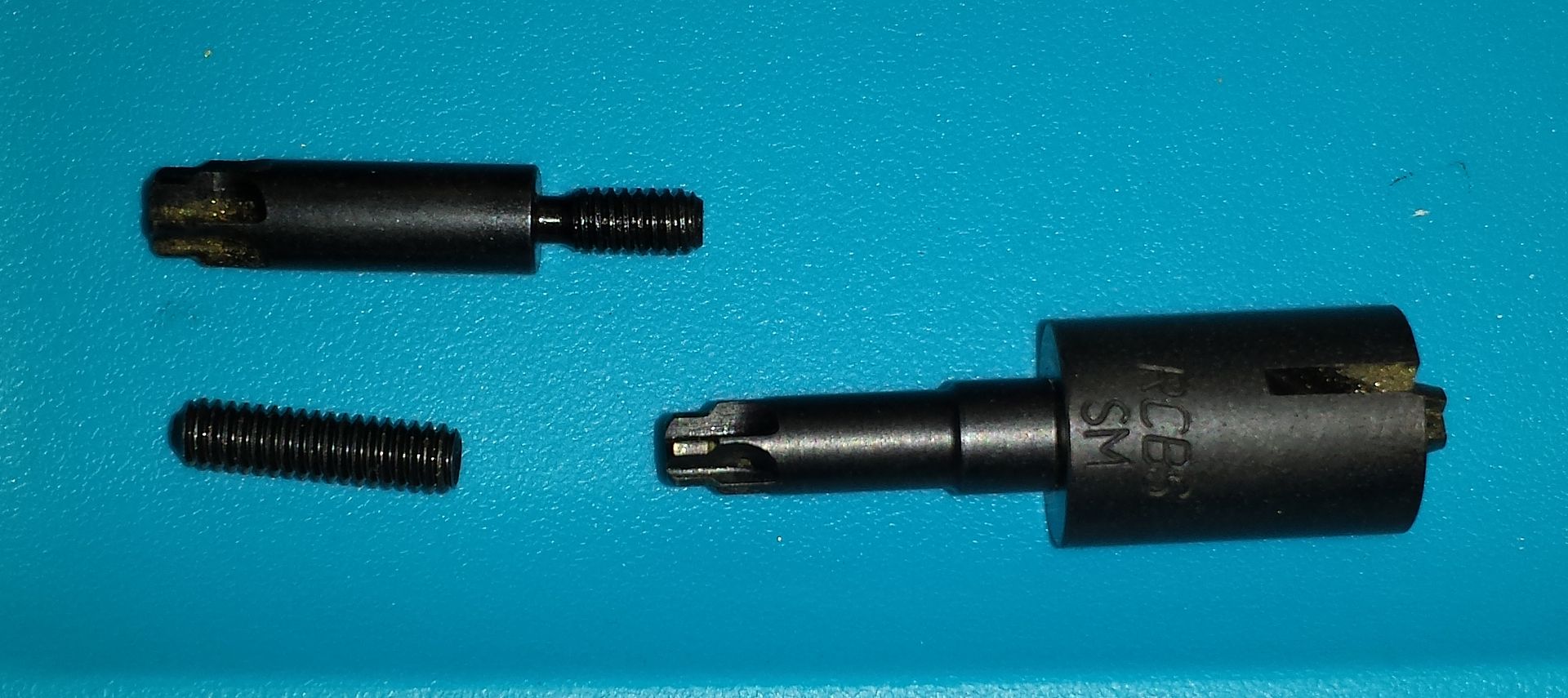

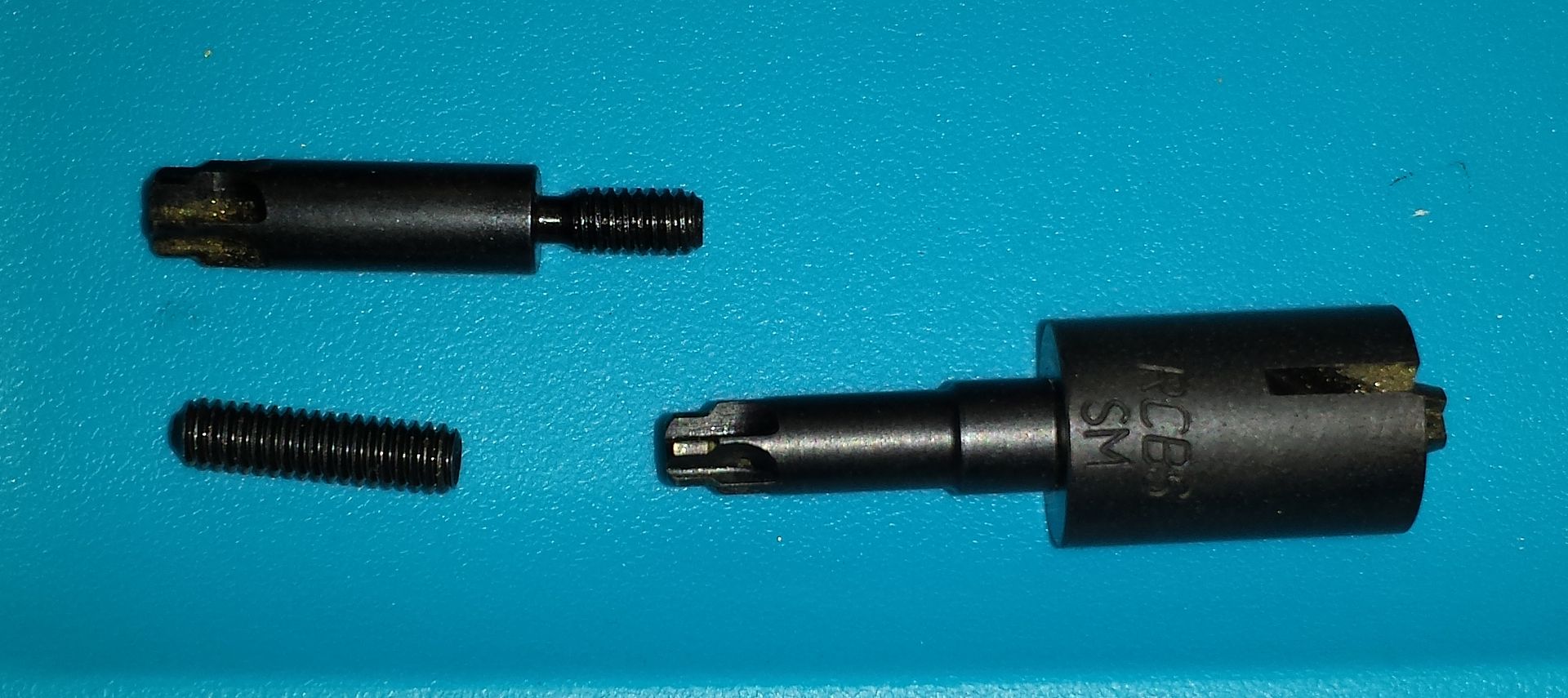

ive used the RCBS military crimp remover (cutter). it works great, but i find it works a LOT better if you use it on somethign with higher RPM than a case prep station... like a small hand drill. the lyman primer pocket reamer threads right into the tool for a great applicatoin for a drill stem - or any 8-32 threaded tool for that matter. The primer pocket reamer works nice as well.

i find this was a MUCH nicer option than using a chamfer tool as you dont have to worry about over reaming your pockets. just spin until it stops cutting and you're good to go.

i suggest wearing gloves (like jersey gloves) while doing this so that if one does bind/lock up on you, you have a much lower risk of getting cut by the case mouth.

i find this was a MUCH nicer option than using a chamfer tool as you dont have to worry about over reaming your pockets. just spin until it stops cutting and you're good to go.

i suggest wearing gloves (like jersey gloves) while doing this so that if one does bind/lock up on you, you have a much lower risk of getting cut by the case mouth.

If you do go with a Dillon, check this place out. http://inlinefabrication.com/collections/dillon

They make a delrin insert that helps center the case really nice. Set up a cardboard box behind the tool so you can just flip the finished case right off and into the box.

They make a delrin insert that helps center the case really nice. Set up a cardboard box behind the tool so you can just flip the finished case right off and into the box.

Originally Posted By: SqueezeI use a chamfer tool holder, that chucks up in a hand drill, or drill press. The slight tapered pocket helps progressives find the primer pocket, too. To me cutting just makes more sense than shearing(swaging).

Squeeze

This is a holder that was custom done for me almost 30 years ago. It will also hold my K&M VLD chamfer tool. Just flipping the tool and putting it in my Mikiata has saved my wrists from carpal tunnel quite nicely. I got a terrible case of tendinitis, lasted six months, using the Dillon.

Greg

Squeeze

This is a holder that was custom done for me almost 30 years ago. It will also hold my K&M VLD chamfer tool. Just flipping the tool and putting it in my Mikiata has saved my wrists from carpal tunnel quite nicely. I got a terrible case of tendinitis, lasted six months, using the Dillon.

Greg