So, my dads brand new 870 is having problems 90% of the time extracting the spent shell. I have an 870 that's 10+ years old and has never had a single problem and I noticed something interesting.

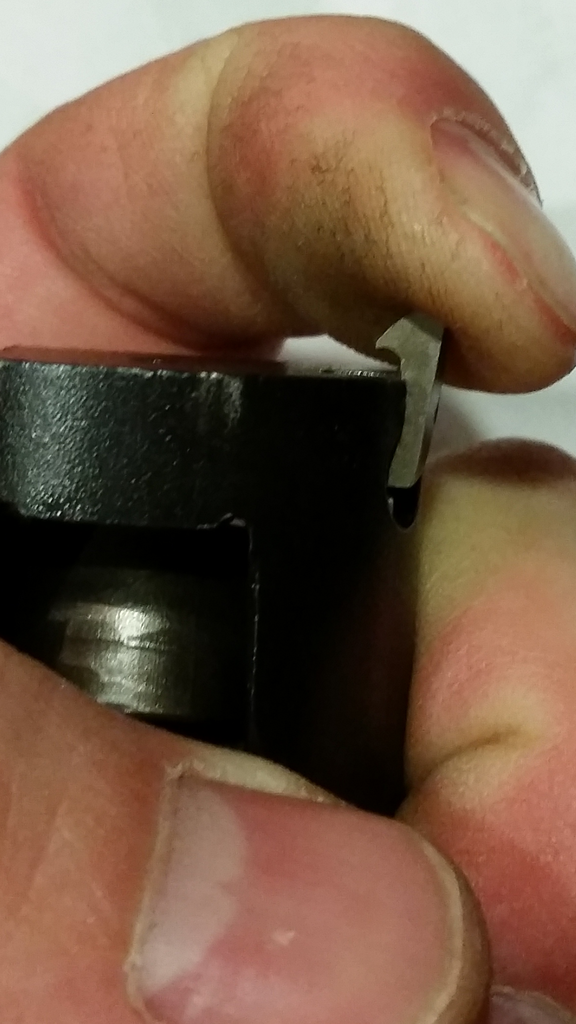

On his (MIM) the extractor will rotate all the way past the side of the bolt. On mine (machined) the extractor hardly rotates back at all. I don't think it even rotates far enough to get past the rim on the shell.

So I put my machined one in his bolt and it acted the same as mine had... extractor will not rotate all the backwards. I ordered a volquartsen for his....and now it does the same thing as his orignal MIM one did!

Which way is correct?? How far should the extractor rotate???

The only way I was able to get his functioning was to stretch the extractor srping ~25% but this seems like a short term fix that won't last.

On his (MIM) the extractor will rotate all the way past the side of the bolt. On mine (machined) the extractor hardly rotates back at all. I don't think it even rotates far enough to get past the rim on the shell.

So I put my machined one in his bolt and it acted the same as mine had... extractor will not rotate all the backwards. I ordered a volquartsen for his....and now it does the same thing as his orignal MIM one did!

Which way is correct?? How far should the extractor rotate???

The only way I was able to get his functioning was to stretch the extractor srping ~25% but this seems like a short term fix that won't last.