Rookie handloader question. I'm reloading for an AR in 5.56 using Hornady dies.I'm not crimping now and haven't had any problems with bullet creep or movement. I've checked OAL in the mag after firing and after loading in the chamber and no movement. But I still would feel better using a bullet with a crimp groove and crimping. What are the pros and cons? And if crimping is the best way what is the best die or procedure? I reload strictly for hunting and want the most reliable and dependable round I can make.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Crimp or not?

- Thread starter eja

- Start date

Not necessary for the AR. If you use the crimp option on the seating die, you will harden the brass at the point of the crimp. Sometimes a crimp will improve accuracy, however most times it will not and very possibly will defeat accuracy. Like so much in shooting, you only find out what happens when you load and shoot. Try it, you might like it. It's just not something I do with mild recoiling cartridges.

Widow maker 223

Well-known member

With properly sized cases and sufficient neck tension, crimp is not needed.

Plant.One

Well-known member

Originally Posted By: Widow maker 223With properly sized cases and sufficient neck tension, crimp is not needed.

this is true in many instances, but also inaccurate for others. there are instances where crimping is mandatory - namely when using plated or cast bullets that require neck expansion to prevent shaving during seating. You have to be able to close that neck up to the proper diameter somehow. while not extremely common in centerfire loads, its not unheard of.

this also applies to folks using a bullet feeder on a progressive press that may need to expand their case necks just a bit to get the bullet feeder die to run correctly.

if you're going to crimp i will encourage you to do so with a separate die and not your seating die.

i use lee factory crimp dies for those cartridges i choose to crimp. It allows you to let your seating die do its job correctly and without interference from the crimping operation, which can be frustrating at times - especially for a new reloader like yourself.

one of the ways to test your neck tension and see if you need to crimp is as follows

setup a dummy cartridge - brass and bullet only, no primer and powder.

load cartridge in a magazine, and chamber from full bolt lock back by hitting the bolt release.

repeat this process 10 times, measuring the OAL after every repetition.

if you get OAL shift, in either direction, crimping can help resolve the issue. The sooner the OAL change happens, the more critically you may wish to think about crimping, especailly if you're up close to max loads.

Although as noted correcting your neck tension will usually fix that issue for you too.

however like anything else reloading - if you do make the change and start crimping - you should redo at least a partial load workup. Any change you make to your recipe, as a safety standard, should follow that rule regardless of its a primer, brass, bullet, powder, oal, or other change like crimp vs non crimped.

plus you never know... your peticular combination of powder, bullet, primer and brass may actually shoot better with a light crimp than it does without. or it could shoot a whole lot worse. The only way to really know for sure is to make up a ladder and do some testing!

HTH

this is true in many instances, but also inaccurate for others. there are instances where crimping is mandatory - namely when using plated or cast bullets that require neck expansion to prevent shaving during seating. You have to be able to close that neck up to the proper diameter somehow. while not extremely common in centerfire loads, its not unheard of.

this also applies to folks using a bullet feeder on a progressive press that may need to expand their case necks just a bit to get the bullet feeder die to run correctly.

if you're going to crimp i will encourage you to do so with a separate die and not your seating die.

i use lee factory crimp dies for those cartridges i choose to crimp. It allows you to let your seating die do its job correctly and without interference from the crimping operation, which can be frustrating at times - especially for a new reloader like yourself.

one of the ways to test your neck tension and see if you need to crimp is as follows

setup a dummy cartridge - brass and bullet only, no primer and powder.

load cartridge in a magazine, and chamber from full bolt lock back by hitting the bolt release.

repeat this process 10 times, measuring the OAL after every repetition.

if you get OAL shift, in either direction, crimping can help resolve the issue. The sooner the OAL change happens, the more critically you may wish to think about crimping, especailly if you're up close to max loads.

Although as noted correcting your neck tension will usually fix that issue for you too.

however like anything else reloading - if you do make the change and start crimping - you should redo at least a partial load workup. Any change you make to your recipe, as a safety standard, should follow that rule regardless of its a primer, brass, bullet, powder, oal, or other change like crimp vs non crimped.

plus you never know... your peticular combination of powder, bullet, primer and brass may actually shoot better with a light crimp than it does without. or it could shoot a whole lot worse. The only way to really know for sure is to make up a ladder and do some testing!

HTH

Brad Phillips

Active member

Originally Posted By: vahunterSome might disagree but I only crimp straight wall cases, 45-70,.44mag,9mm and .380. Never crimped AR cases in either .223 or 6x45.

Me, too

Me, too

MotoHunter

New member

If you do decide to crimp, use a "tapered Crimp" not a "roll" crimp.

Widow maker 223

Well-known member

Originally Posted By: Plant.OneOriginally Posted By: Widow maker 223With properly sized cases and sufficient neck tension, crimp is not needed.

this is true in many instances, but also inaccurate for others. there are instances where crimping is mandatory - namely when using plated or cast bullets that require neck expansion to prevent shaving during seating. You have to be able to close that neck up to the proper diameter somehow. while not extremely common in centerfire loads, its not unheard of.

this also applies to folks using a bullet feeder on a progressive press that may need to expand their case necks just a bit to get the bullet feeder die to run correctly.

if you're going to crimp i will encourage you to do so with a separate die and not your seating die.

i use lee factory crimp dies for those cartridges i choose to crimp. It allows you to let your seating die do its job correctly and without interference from the crimping operation, which can be frustrating at times - especially for a new reloader like yourself.

one of the ways to test your neck tension and see if you need to crimp is as follows

setup a dummy cartridge - brass and bullet only, no primer and powder.

load cartridge in a magazine, and chamber from full bolt lock back by hitting the bolt release.

repeat this process 10 times, measuring the OAL after every repetition.

if you get OAL shift, in either direction, crimping can help resolve the issue. The sooner the OAL change happens, the more critically you may wish to think about crimping, especailly if you're up close to max loads.

Although as noted correcting your neck tension will usually fix that issue for you too.

however like anything else reloading - if you do make the change and start crimping - you should redo at least a partial load workup. Any change you make to your recipe, as a safety standard, should follow that rule regardless of its a primer, brass, bullet, powder, oal, or other change like crimp vs non crimped.

plus you never know... your peticular combination of powder, bullet, primer and brass may actually shoot better with a light crimp than it does without. or it could shoot a whole lot worse. The only way to really know for sure is to make up a ladder and do some testing!

HTH

The OP is talking about .223 so my statement is 100% true!! He didnt ask about any other calibers.

this is true in many instances, but also inaccurate for others. there are instances where crimping is mandatory - namely when using plated or cast bullets that require neck expansion to prevent shaving during seating. You have to be able to close that neck up to the proper diameter somehow. while not extremely common in centerfire loads, its not unheard of.

this also applies to folks using a bullet feeder on a progressive press that may need to expand their case necks just a bit to get the bullet feeder die to run correctly.

if you're going to crimp i will encourage you to do so with a separate die and not your seating die.

i use lee factory crimp dies for those cartridges i choose to crimp. It allows you to let your seating die do its job correctly and without interference from the crimping operation, which can be frustrating at times - especially for a new reloader like yourself.

one of the ways to test your neck tension and see if you need to crimp is as follows

setup a dummy cartridge - brass and bullet only, no primer and powder.

load cartridge in a magazine, and chamber from full bolt lock back by hitting the bolt release.

repeat this process 10 times, measuring the OAL after every repetition.

if you get OAL shift, in either direction, crimping can help resolve the issue. The sooner the OAL change happens, the more critically you may wish to think about crimping, especailly if you're up close to max loads.

Although as noted correcting your neck tension will usually fix that issue for you too.

however like anything else reloading - if you do make the change and start crimping - you should redo at least a partial load workup. Any change you make to your recipe, as a safety standard, should follow that rule regardless of its a primer, brass, bullet, powder, oal, or other change like crimp vs non crimped.

plus you never know... your peticular combination of powder, bullet, primer and brass may actually shoot better with a light crimp than it does without. or it could shoot a whole lot worse. The only way to really know for sure is to make up a ladder and do some testing!

HTH

The OP is talking about .223 so my statement is 100% true!! He didnt ask about any other calibers.

It sounds as though you are having zero issues with your loads and have taken the proper steps to insure that you are having no bullet movement.

As stated, it all about proper sizing and neck tension.

I use NO crimp on my .223's..........awhile back I had to pull about 50 rounds because of a powder weight issue, (my fault). I used a kinetic bullet puller to break them all down and the force it took to pull the bullets was more than what any AR can produce.

Why try to fix something that's not broke?

Her Kitty Kitty

As stated, it all about proper sizing and neck tension.

I use NO crimp on my .223's..........awhile back I had to pull about 50 rounds because of a powder weight issue, (my fault). I used a kinetic bullet puller to break them all down and the force it took to pull the bullets was more than what any AR can produce.

Why try to fix something that's not broke?

Her Kitty Kitty

Last edited:

Plant.One

Well-known member

Originally Posted By: Widow maker 223The OP is talking about .223 so my statement is 100% true!! He didnt ask about any other calibers.

your statement was concrete without any consideration for how other folks may reload.

just because you dont do it, doesnt mean its the end all to be all. that would be no different than you saying "i reload on a single stage, nobody should ever even consider a progressive press" or "i use ball powder, nobody should ever use extruded powders". Thats one of the beauties of reloading - it allows each of us to tailor our loads to OUR needs and desires.

additionally, please point out where in my post i said anything about other calibers - my post was 100% caliber non specific in that regard.

if you bother to read my post - leaving your butthurt at the door before you do - i do in fact agree with you that in most cases, proper neck tension does in fact preclude the NEED for crimping.

Quote:Although as noted correcting your neck tension will usually fix that issue for you too.

the OP's desire to learn about crimping should not be shut down just because its not something you do or feel is necessary. better to give someone the proper information on where a crimp may be applicable - or even necessary - and a safe method to find out if it meets their reloading needs and let them test in a safe manner which will work better for their firearm.

your statement was concrete without any consideration for how other folks may reload.

just because you dont do it, doesnt mean its the end all to be all. that would be no different than you saying "i reload on a single stage, nobody should ever even consider a progressive press" or "i use ball powder, nobody should ever use extruded powders". Thats one of the beauties of reloading - it allows each of us to tailor our loads to OUR needs and desires.

additionally, please point out where in my post i said anything about other calibers - my post was 100% caliber non specific in that regard.

if you bother to read my post - leaving your butthurt at the door before you do - i do in fact agree with you that in most cases, proper neck tension does in fact preclude the NEED for crimping.

Quote:Although as noted correcting your neck tension will usually fix that issue for you too.

the OP's desire to learn about crimping should not be shut down just because its not something you do or feel is necessary. better to give someone the proper information on where a crimp may be applicable - or even necessary - and a safe method to find out if it meets their reloading needs and let them test in a safe manner which will work better for their firearm.

I have shot thousands of rounds through my AR rifles without crimping. A buddy of mine suggested crimping as a method of reducing fliers with my cheap blasting ammo that I toss together with mixed brass with unknown times fired. I bought a Lee factory crimp die and I'll be darned, group sizes did improve. With good brass I don't think it is necessary, but it doesn't seem to hurt.

Plantone, you need to try the same load without crimping. Crimping is VooDoo science based on consistent case lengths. If a case is longer, it gets one heck of a crimp, while a short case gets little crimp.

Also, a slight taper crimp maybe a whole lot better than a roll crimp. Variations in neck thickness will change the amount of grip with a taper crimp...more Voo Doo science.

When taper crimping 45 ACP brass, I had to sort my brass by maker, then have several different dies to make up for brands that I had with thinner/thicker walls....trying to develop 50 yard loads for killing a coyote with. Production dies can be all over the map in terms of ID. I ended up with one heck of an accurate load in the end.

Also, a slight taper crimp maybe a whole lot better than a roll crimp. Variations in neck thickness will change the amount of grip with a taper crimp...more Voo Doo science.

When taper crimping 45 ACP brass, I had to sort my brass by maker, then have several different dies to make up for brands that I had with thinner/thicker walls....trying to develop 50 yard loads for killing a coyote with. Production dies can be all over the map in terms of ID. I ended up with one heck of an accurate load in the end.

Last edited:

Plant.One

Well-known member

Originally Posted By: ackleymanPlantone, you need to try the same load without crimping. Crimping is VooDoo science based on consistent case lengths. If a case is longer, it gets one heck of a crimp, while a short case gets little crimp.

Also, a slight taper crimp maybe a whole lot better than a roll crimp. Variations in neck thickness will change the amount of grip with a taper crimp...more Voo Doo science.

When taper crimping 45 ACP brass, I had to sort my brass by maker, then have several different dies to make up for brands that I had with thinner/thicker walls....trying to develop 50 yard loads for killing a coyote with. Production dies can be all over the map in terms of ID. I ended up with one heck of an accurate load in the end.

i agree, the barrel and that bullet need a lot more testing before i'm done. I wasnt suggesting that crimping IS the answer in any way, just that blasting crimping as a whole is just as foolish as saying crimping is the only way to go. Testing, as you rightly pointed out will be the only way to really find out if a crimped load is better in that brrel or not.

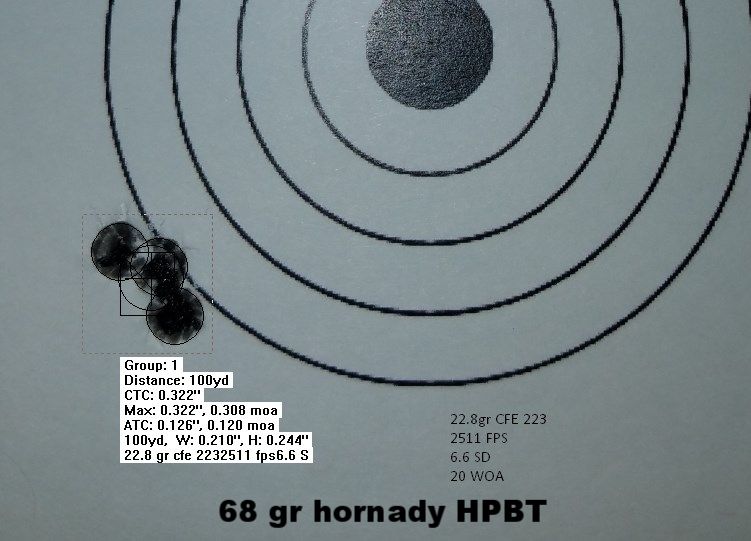

that image just happens to show a load combination that, lightly taper crimped with my FCD, produced good results, in my gun.

My intent in posting it was to simply point out that crimping isnt necessarily bad. Sometimes it works out well, other times it doesnt.

just like a lot of other factors - no two barrels are going to respond to any specific little thing the same - crimping included.

anyway - anything that gives you an excuse to spend some more time pulling the trigger, even if its just for the sake of gathering data on your gun/barrel is always a good thing

Also, a slight taper crimp maybe a whole lot better than a roll crimp. Variations in neck thickness will change the amount of grip with a taper crimp...more Voo Doo science.

When taper crimping 45 ACP brass, I had to sort my brass by maker, then have several different dies to make up for brands that I had with thinner/thicker walls....trying to develop 50 yard loads for killing a coyote with. Production dies can be all over the map in terms of ID. I ended up with one heck of an accurate load in the end.

i agree, the barrel and that bullet need a lot more testing before i'm done. I wasnt suggesting that crimping IS the answer in any way, just that blasting crimping as a whole is just as foolish as saying crimping is the only way to go. Testing, as you rightly pointed out will be the only way to really find out if a crimped load is better in that brrel or not.

that image just happens to show a load combination that, lightly taper crimped with my FCD, produced good results, in my gun.

My intent in posting it was to simply point out that crimping isnt necessarily bad. Sometimes it works out well, other times it doesnt.

just like a lot of other factors - no two barrels are going to respond to any specific little thing the same - crimping included.

anyway - anything that gives you an excuse to spend some more time pulling the trigger, even if its just for the sake of gathering data on your gun/barrel is always a good thing

Brad Phillips

Active member

Originally Posted By: ackleymanWhile I do not practice crimping rifle cases other that lever gun's, many, many people claim that the lee crimp die is magic, especially in the 22 Hornet.

The stuff that I crimp, straight wall cases or levergun stuff, get done with a Lee factory crimp die.

The stuff that I crimp, straight wall cases or levergun stuff, get done with a Lee factory crimp die.