wachtelhund1

Member

This is not a firearm, but I would like to share my stock duplicating machine build. This has been a long term project, several years. It is actually my third duplicating machine. I made a thumbhole stock for my HK 630 with the second one. The second one rotated the original stock and one being made by three sprockets and a #20 chain. It worked, but it had backlash in it if the pieces were rotated backwards. In this version I replaced the sprockets and chain with five 2.5" 60 tooth robot gears, staggered to make 9" center to center. It is mostly made with .5" and .375" aluminum plate purchased from a salvage yard for $1.00 per pound. It is setup on a two foot wide by six foot long table and it is heavy. I recently finished it and have made a walnut stock for my Ruger American Rimfire in .17HMR, which I will show in a separate post. Please pay no attention to the clutter of tools on the table.

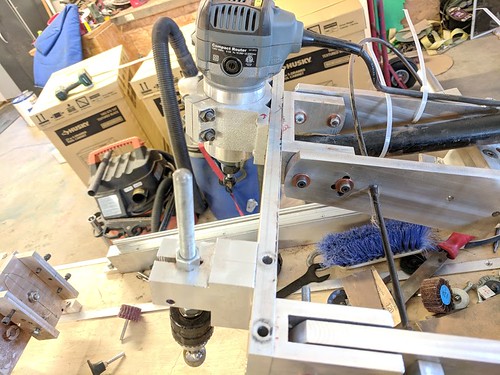

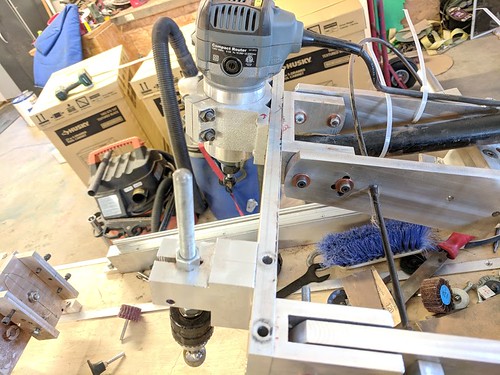

I'm using a cheap Menards router. The styluses and router are 9" ctc. I use mostly regular router bits.

Its set up on linear rails and bearings. In this picture I show one of the brakes which are always closed until I squeeze the handle.

The brake handle. When squeezed both brakes are released.

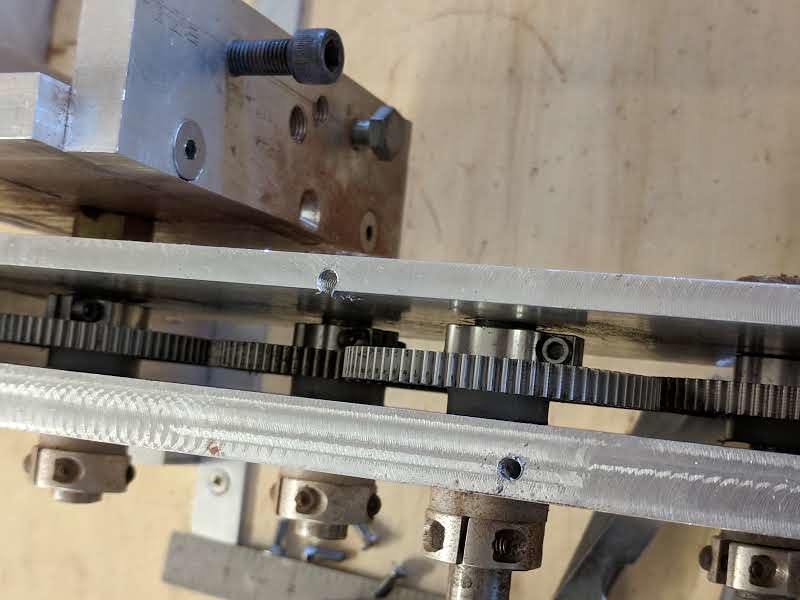

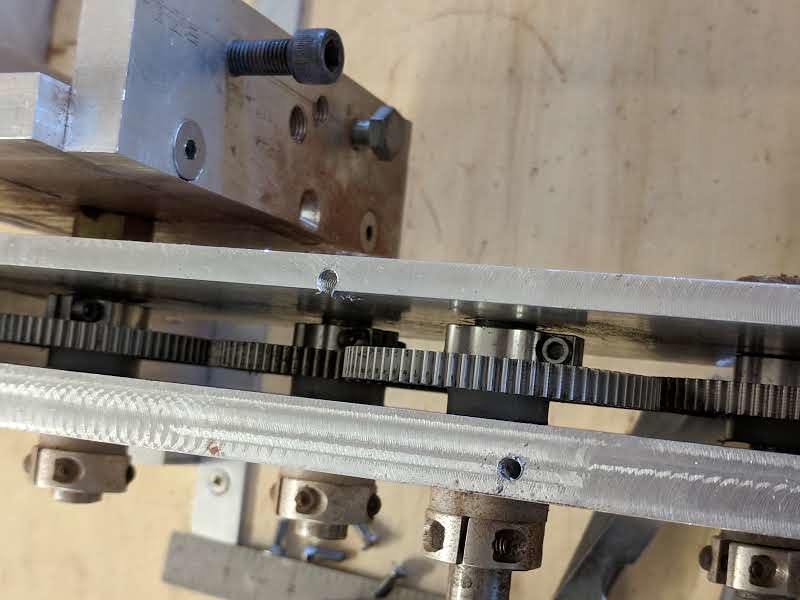

The turning mechanism. Again 9" ctc.

Beginning to cut my first stock for a Ruger American Rimfire in .17HMR. The walnut is 10 year old airdried from CA, 2.5" thick, 32" long.

I'm using a cheap Menards router. The styluses and router are 9" ctc. I use mostly regular router bits.

Its set up on linear rails and bearings. In this picture I show one of the brakes which are always closed until I squeeze the handle.

The brake handle. When squeezed both brakes are released.

The turning mechanism. Again 9" ctc.

Beginning to cut my first stock for a Ruger American Rimfire in .17HMR. The walnut is 10 year old airdried from CA, 2.5" thick, 32" long.

Last edited: