Playing Around On The Mill

- Thread starter GNERGY

- Start date

I wanted to do something different to some uppers and some lowers. The lowers my friend manufactures as 80% ers. and the upper still in the white he makes also. The fit on his are amazing, no wobble, he reams the holes so when you put your pins in they are tight. The other 2 uppers are Gun Tec.

I had them annodized and are going to use them on my 25 DTI build. Just getting it put together and hopefully will have pics in a day or 2.

Thanks for looking.

Tarey

I had them annodized and are going to use them on my 25 DTI build. Just getting it put together and hopefully will have pics in a day or 2.

Thanks for looking.

Tarey

Maybe a stupid question from someone with limted machining experience. Is there any concern with the barrel moveing when fluting and taking that much material? I have no idea what material a barrel is made of but have experianced some alloys stress relieving and moveing when machineing

Thanks for the kind words.

I have been a Maintenance Machinist for 40 yrs. and have a Lathe and a Mill in the garage.

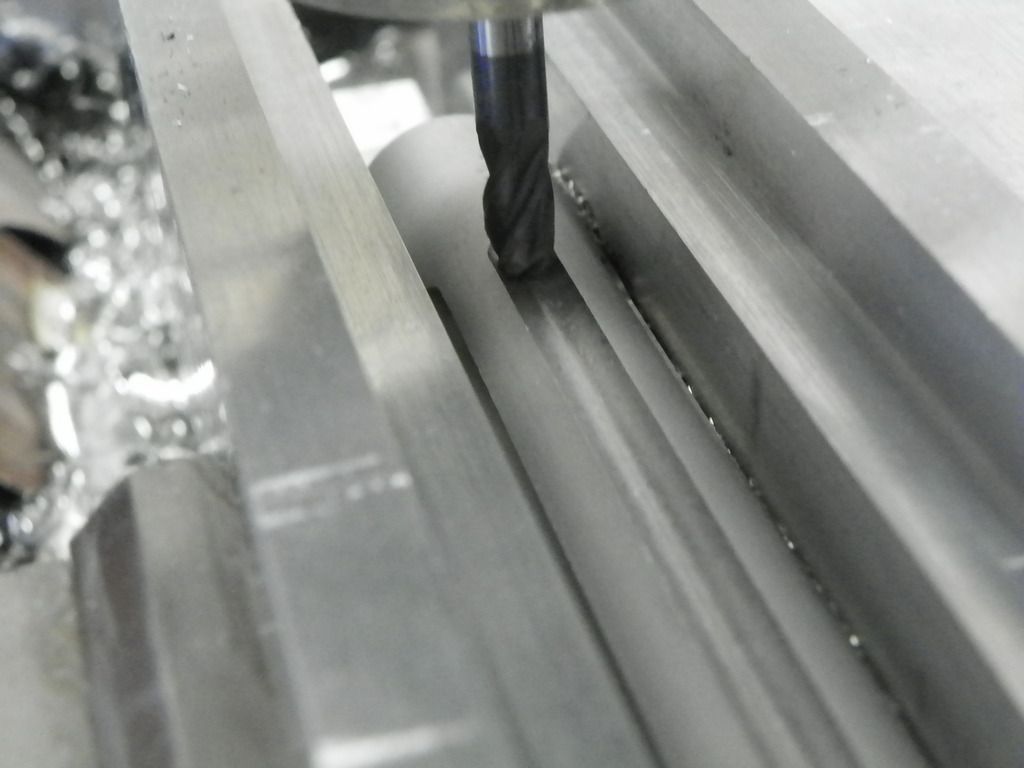

grinder, I held the part I was machining centered in the vise and only went .010 deep on each cut, so it was a lot of back and forth passes, so no heat was generated at all. Most barrels are stressed releved some before and some after machining before they leave the barrel maker.

Tarey

I have been a Maintenance Machinist for 40 yrs. and have a Lathe and a Mill in the garage.

grinder, I held the part I was machining centered in the vise and only went .010 deep on each cut, so it was a lot of back and forth passes, so no heat was generated at all. Most barrels are stressed releved some before and some after machining before they leave the barrel maker.

Tarey

Looks good!! I to was a Maintenance Machinist/ Fabricator and jack of all trades....master of none for 28 year. My plant moved from Okla to Kentucky and left me in Okla. Now I have a Dremel, a drill press and a grinder. Anything complicated and I'm SOL! But your stuff looks great.

Last edited:

brshooter

New member

Fluting looks awesome. Nice Job! So do the lowers.

Question on your lowers. I bought four 80% lowers a few years ago and when I talked to the company who anodized them for me, I was told they had to do them while they were still 80%. They couldn't do as 100% as they had to be logged into their book and there would not be a serial number to do this. This was from the company who does the coating for Aero and Mega. Has that been any issue for you finding someone who will coat them as 100% without a serial number?

Question on your lowers. I bought four 80% lowers a few years ago and when I talked to the company who anodized them for me, I was told they had to do them while they were still 80%. They couldn't do as 100% as they had to be logged into their book and there would not be a serial number to do this. This was from the company who does the coating for Aero and Mega. Has that been any issue for you finding someone who will coat them as 100% without a serial number?

LARUEminati

Active member

Looks good

brshooter, I would just call around to see who does the class 3 hard anodize. A local place did mine no questions asked. I had 11 pieces done and it cost $125. When I was younger I worked at a gun shop and we got a bunch of Ithaca shotguns with no serial numbers. So we called ATF and told them, they just said write down no serial number on the form when you sell them ( didn't seem like no big concern to them ).

Thanks for the nice comments gentlemen.

Tarey

Thanks for the nice comments gentlemen.

Tarey