You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stabilizing wood questions

- Thread starter ronbeaux

- Start date

dogcatcher

Active member

I have tried the home versions, they are okay, but I sold mine and went back to using the pros. I like their results a lot better. The cost savings were not worth the lessor quality of the home stabilizing.

TNYotehntr

Active member

Originally Posted By: dogcatcherI have tried the home versions, they are okay, but I sold mine and went back to using the pros. I like their results a lot better. The cost savings were not worth the lessor quality of the home stabilizing.

Wish I'd have listened to this kind of advice before I bought a rig... you want to buy mine? LOL

Wish I'd have listened to this kind of advice before I bought a rig... you want to buy mine? LOL

bearmanric

New member

Rocky1

New member

Originally Posted By: ronbeauxI read that but I see all these kits for sale on ebay and the videos and it just doesn't look that hard. I just want the right equipment. I saw where glass is a must for the lid, not plastic, so at least that is a start.

From what I've been reading and watching on the Net, I don't know that glass is really that big an issue. A lot of guys are getting spun up over nothing with the hairline cracks in the plastic on their chamber. "The Internet says" sorta thing.

Gentleman is selling glass chambers, claims them to be superior, and they no doubt are in certain respects, that I will not argue in anyway. But... if you watch enough of his videos, even he tells you that just because the plastic has a few small hairline fractures showing, it doesn't mean it's going to fail or leak. That the hairline fractures of the plastic are normal and don't hurt a thing.

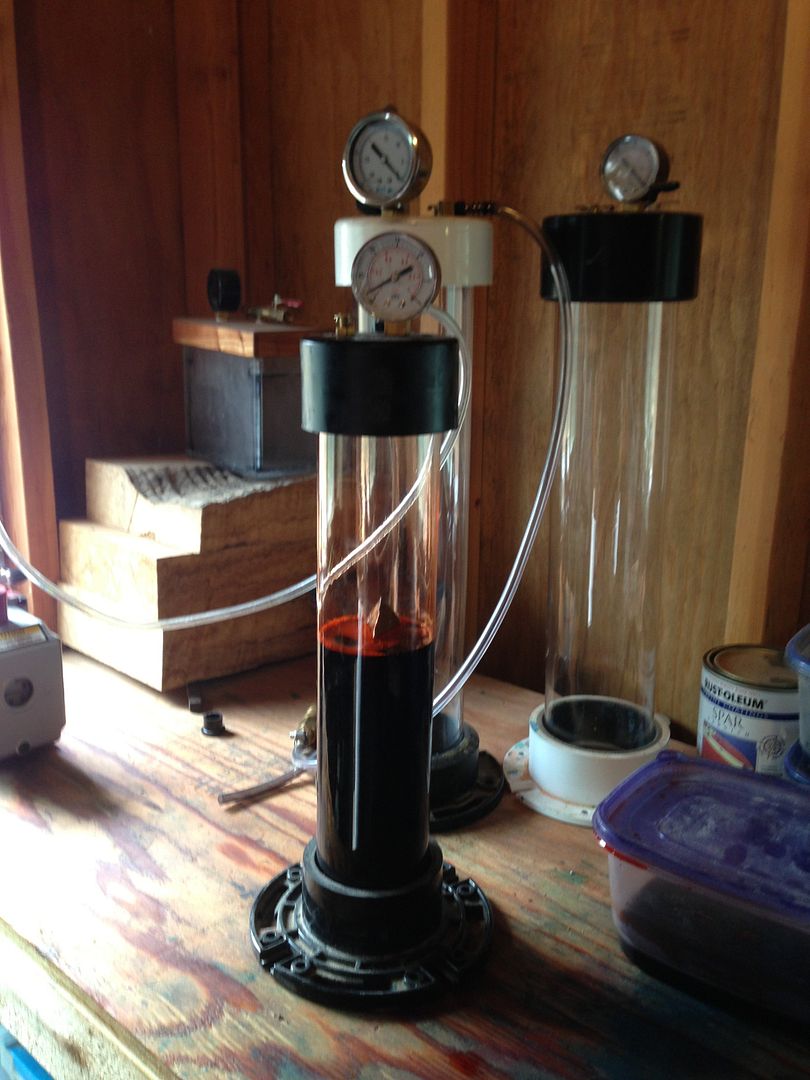

I purchased aluminum pots with acrylic lids a couple years ago, while speculating on lathe purchase, (haven't used them yet, probably going to today however, I have 3 pieces of oak crotch stock that I'm trying to salvage and I want to stabilize them before trying to turn them). However, if I had it to do over, with glass pots available, I'd spend the extra money on glass, just because it's fun to watch, easier to see what's going on, and make sure that you have thorough penetration. And, for that reason alone, I'd go glass if I were purchasing now. I'd also be very tempted to purchase a dry pot as it seems logical they are more efficient/faster/less wasteful of resin/easier to add resin.

- don't recall which one in the series he get's into dry chambers, but it's toward the end of the 6 in the series.

As for quality of the stabilizing job, DIY vs. Professionally Stabilized, I want to get into turning a few bowls and other things and sending large bowl sized chunks of partially turned firewood off to have it stablized is, 1.) cost prohibitive, and 2.) not feasible from a perspective of fragility. Not only would your piece be subject to be destroyed in shipping, it would be apt to dry and crack before it made it to the stabilizing pot.

From what I've been reading and watching on the Net, I don't know that glass is really that big an issue. A lot of guys are getting spun up over nothing with the hairline cracks in the plastic on their chamber. "The Internet says" sorta thing.

Gentleman is selling glass chambers, claims them to be superior, and they no doubt are in certain respects, that I will not argue in anyway. But... if you watch enough of his videos, even he tells you that just because the plastic has a few small hairline fractures showing, it doesn't mean it's going to fail or leak. That the hairline fractures of the plastic are normal and don't hurt a thing.

I purchased aluminum pots with acrylic lids a couple years ago, while speculating on lathe purchase, (haven't used them yet, probably going to today however, I have 3 pieces of oak crotch stock that I'm trying to salvage and I want to stabilize them before trying to turn them). However, if I had it to do over, with glass pots available, I'd spend the extra money on glass, just because it's fun to watch, easier to see what's going on, and make sure that you have thorough penetration. And, for that reason alone, I'd go glass if I were purchasing now. I'd also be very tempted to purchase a dry pot as it seems logical they are more efficient/faster/less wasteful of resin/easier to add resin.

- don't recall which one in the series he get's into dry chambers, but it's toward the end of the 6 in the series.

As for quality of the stabilizing job, DIY vs. Professionally Stabilized, I want to get into turning a few bowls and other things and sending large bowl sized chunks of partially turned firewood off to have it stablized is, 1.) cost prohibitive, and 2.) not feasible from a perspective of fragility. Not only would your piece be subject to be destroyed in shipping, it would be apt to dry and crack before it made it to the stabilizing pot.

bearmanric

New member

ronbeaux

New member

Now we are talking! They got stainless pots with glass or poly carbonate lids and they sell vacumn pumps. So I was thinking go for the pots that hold a vacumn well and allow you to see what is happening, use cactus juice and and get a decent oven for baking.

Any thoughts on vacumn pumps? Or air compressor(which I have) and a vacumn generator?

Any thoughts on vacumn pumps? Or air compressor(which I have) and a vacumn generator?

Rocky1

New member

Vacuum pump wasn't bad on E-Bay when I bought mine. They had the pot/pump kit, but I dug and found all seperately. Wound up with less in 2 pots and pump than they were selling the pot/pump kit for. Think the pump ran me right at $100, picked up a larger pot, I think that one is a 5 gallon, and a small one, quart size, for little jobs. I was $20 - $30 less than the 5 gallon and pump kit.

http://www.ebay.com/sch/items/?_nkw=Vacu...&rmvSB=true

Watch your CFM when comparing prices on pumps. Of course, the more CFM the faster you get down to desired vacuum. Mine is a 5 CFM. There's a 7 CFM listed there for $130...

http://www.ebay.com/itm/HOMCOM-Single-St...7IAAOSwe-FU9Wtz

5 CFM for $80 ...

http://www.ebay.com/sch/i.html_odkw=Vacu...rs&_sacat=0

Then if you search Vacuum Chamber seperately, you come up with an endless assortment of pots of all nature.

http://www.ebay.com/sch/i.html?_odkw=Vac...rs&_sacat=0

Both of my pots are the Best Value Vacs pots, Orange trim on the Aluminum Pot. Seem to be well built, wish I had used them more so I could tell you how wonderful they are/or not.

Don't forget to ask everyone what sort of juice they're using. Already got Rick's input there. Nick is using the ZK-TR90.

But, after you get your pot and start looking, you'll find there are at least a half dozen different varieties of stabilizing resin. Most are comparably priced, all do the same thing, all have similar working properties. I have a quart of 2 of them in the barn to try now. While I do sincerely value all these guys' input, down here in Florida the humidity is through the roof most of the time and I'm wondering what affect that may have on some of their working properties.

"Good oven"... General consensus from what I've been reading is a toaster oven that doesn't run on a timed cycle unless it goes long enough to cure the resin. I have a cheap one in the barn, but it'll only run 12 minutes. The one we have in the house is programmable, but it wasn't exactly cheap. Not like you're going to have a big oven full of goodies to put in it to begin with, unless you're turning large bowls. I just bought a LEM Smoker that is 2 - 4 times the size of a toaster oven, that'll reach adequate temperature for most of the resins, and I could put the 5 gallon pot in it, let alone it's contents, but it was over $200. I wouldn't do propane on the oven, make sure it's electric. Electric is a drier heat than gas or propane.

http://www.ebay.com/sch/items/?_nkw=Vacu...&rmvSB=true

Watch your CFM when comparing prices on pumps. Of course, the more CFM the faster you get down to desired vacuum. Mine is a 5 CFM. There's a 7 CFM listed there for $130...

http://www.ebay.com/itm/HOMCOM-Single-St...7IAAOSwe-FU9Wtz

5 CFM for $80 ...

http://www.ebay.com/sch/i.html_odkw=Vacu...rs&_sacat=0

Then if you search Vacuum Chamber seperately, you come up with an endless assortment of pots of all nature.

http://www.ebay.com/sch/i.html?_odkw=Vac...rs&_sacat=0

Both of my pots are the Best Value Vacs pots, Orange trim on the Aluminum Pot. Seem to be well built, wish I had used them more so I could tell you how wonderful they are/or not.

Don't forget to ask everyone what sort of juice they're using. Already got Rick's input there. Nick is using the ZK-TR90.

But, after you get your pot and start looking, you'll find there are at least a half dozen different varieties of stabilizing resin. Most are comparably priced, all do the same thing, all have similar working properties. I have a quart of 2 of them in the barn to try now. While I do sincerely value all these guys' input, down here in Florida the humidity is through the roof most of the time and I'm wondering what affect that may have on some of their working properties.

"Good oven"... General consensus from what I've been reading is a toaster oven that doesn't run on a timed cycle unless it goes long enough to cure the resin. I have a cheap one in the barn, but it'll only run 12 minutes. The one we have in the house is programmable, but it wasn't exactly cheap. Not like you're going to have a big oven full of goodies to put in it to begin with, unless you're turning large bowls. I just bought a LEM Smoker that is 2 - 4 times the size of a toaster oven, that'll reach adequate temperature for most of the resins, and I could put the 5 gallon pot in it, let alone it's contents, but it was over $200. I wouldn't do propane on the oven, make sure it's electric. Electric is a drier heat than gas or propane.

bearmanric

New member

Good luck. Rick

Rocky1

New member

I would think once you impregnate it, that it's no longer a matter of it being bone, it becomes a whatever your resin is, Polymer or whatever.

As far as bone itself standing up to 200 degrees, you cook goodies in the oven all the time at far higher temps and it doesn't all come out mush; the bone doesn't fragment or disintegrate as a result of the heat in the process, in fact your dog will have a field day chewing on it for several days thereafter, so without any hands on experience on that one, I'd have to say, "Yeah, more than likely."

As far as bone itself standing up to 200 degrees, you cook goodies in the oven all the time at far higher temps and it doesn't all come out mush; the bone doesn't fragment or disintegrate as a result of the heat in the process, in fact your dog will have a field day chewing on it for several days thereafter, so without any hands on experience on that one, I'd have to say, "Yeah, more than likely."

Rocky1

New member

Originally Posted By: ronbeauxHere is what I am looking at

http://www.ebay.com/itm/1-5-Gal-SS-Slick...:g:QrcAAOSwQPlV

Wouldn't be tough to convert mine to a glass lid, drill one hole in the side of the pot and move the plumbing.

http://www.ebay.com/itm/1-5-Gal-SS-Slick...:g:QrcAAOSwQPlV

Wouldn't be tough to convert mine to a glass lid, drill one hole in the side of the pot and move the plumbing.

Rocky1

New member

I'm going to put in a "steer clear of the Best Value Vac pots!" here.

Dug my little one out the other day to stabilize a few pieces of oak crotch, It's 2 years old, never been out of the box. I couldn't get it to hold vacuum at all. Seemed to be hoses, so I added hose clamps, helped a little, but still no luck. Removed the straight barbed fitting on the vaccum line, attached the hose to the barbed fitting on the ball valve, and installed a radiator pet cock for a bleeder valve, still no luck, although it did get better. Tightened the nuts on all the fittings after seeing bubbles popping up around each of the ports, still no luck. At this point it will bleed down from 29.5 inches of vaccum to nothing in about 10 minutes; was 45 seconds when I started, still getting air bubbles popping up under the lid around the suction port.

Have been running it, holding vacuum on it for a few minutes to 15 minutes or so every time I got out to the shop, over the course of 2 - 3 days now. Still getting some air out of my pieces, one was dense enough it didn't bubble much to begin with and hasn't floated at all, one has soaked up enough Cactus Juice that it no longer floats, the other still surfaces when weight is removed. So it is at least making headway.

Then last night, after only maybe an hour or so of vacuum actually being applied, at best, and the lid sitting on the pot for 2-3 days now, I fired the pump up and the cover started crazing. Now each time I start it, the lid cracks more and more, and it appears I may have to seek a glass cover much sooner than I anticipated! Wouldn't swear to it, but if I had to guess, the lid on this thing is breaking down rapidly as a result of prolonged exposure to the Cactus Juice fumes, and what little Juice has splattered up there from all the little bitty bubbles popping.

Not a happy camper, to say the least!!

Hoping the bigger pot actually works like it's supposed to, and stands up better than this little one has.

Aside from that, the stock within is living up to my expectations and is really looking amazing!

Went back and looked at their ad and since I'm not the only one that has bought one of these for this purpose I'm going to assume this wasn't there long ago when I purchased mine, but it now says way down at the bottom o the product description, 3/4 of the way down the page...

Quote:

Compatibility Explanation:

• BestValueVac® Chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers. The lid may only be cleaned with soapy water.

• ShatterVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents.

• GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization. The lid may be cleaned with any solvent or cleaning agent.

Dug my little one out the other day to stabilize a few pieces of oak crotch, It's 2 years old, never been out of the box. I couldn't get it to hold vacuum at all. Seemed to be hoses, so I added hose clamps, helped a little, but still no luck. Removed the straight barbed fitting on the vaccum line, attached the hose to the barbed fitting on the ball valve, and installed a radiator pet cock for a bleeder valve, still no luck, although it did get better. Tightened the nuts on all the fittings after seeing bubbles popping up around each of the ports, still no luck. At this point it will bleed down from 29.5 inches of vaccum to nothing in about 10 minutes; was 45 seconds when I started, still getting air bubbles popping up under the lid around the suction port.

Have been running it, holding vacuum on it for a few minutes to 15 minutes or so every time I got out to the shop, over the course of 2 - 3 days now. Still getting some air out of my pieces, one was dense enough it didn't bubble much to begin with and hasn't floated at all, one has soaked up enough Cactus Juice that it no longer floats, the other still surfaces when weight is removed. So it is at least making headway.

Then last night, after only maybe an hour or so of vacuum actually being applied, at best, and the lid sitting on the pot for 2-3 days now, I fired the pump up and the cover started crazing. Now each time I start it, the lid cracks more and more, and it appears I may have to seek a glass cover much sooner than I anticipated! Wouldn't swear to it, but if I had to guess, the lid on this thing is breaking down rapidly as a result of prolonged exposure to the Cactus Juice fumes, and what little Juice has splattered up there from all the little bitty bubbles popping.

Not a happy camper, to say the least!!

Hoping the bigger pot actually works like it's supposed to, and stands up better than this little one has.

Aside from that, the stock within is living up to my expectations and is really looking amazing!

Went back and looked at their ad and since I'm not the only one that has bought one of these for this purpose I'm going to assume this wasn't there long ago when I purchased mine, but it now says way down at the bottom o the product description, 3/4 of the way down the page...

Quote:

Compatibility Explanation:

• BestValueVac® Chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers. The lid may only be cleaned with soapy water.

• ShatterVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents.

• GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization. The lid may be cleaned with any solvent or cleaning agent.